Stackable Storage Bins: Types, Uses, and Organizing Tips

Outline:

– The Space-Saving Logic of Stackable Bins

– Types, Materials, and Design Features

– Planning the Perfect Fit: Sizing, Capacity, and Safety

– Real-World Setups: Home, Garage, Office, and Small Business

– Conclusion and Long-Term Organizing Playbook

The Space-Saving Logic of Stackable Bins

Stackable storage bins solve a familiar problem: flat surfaces attract clutter, and irregular containers waste precious vertical room. By standardizing footprints and making walls do the work, stacks transform scattered items into a neat column that is easy to see, reach, and move. In small apartments, busy households, and lean stockrooms, even a basic 3-bin stack can reclaim floor area while keeping items grouped by purpose. The gains feel immediate because you are compressing air and gaps, not your workflow. Instead of balancing odd boxes that slump or collapse, stack-compatible bins lock into one another or sit in stable alignment, turning height into honest capacity.

The logic extends beyond tidiness. Standardized bins reduce decision fatigue: once a size and style are chosen, you can repeat that choice across rooms and tasks. This creates predictable “parking spots” for objects, which is a subtle but powerful form of time savings. Many people notice that when container shapes and labels are consistent, retrieval time goes down and reset time (putting things back) becomes automatic. A modest investment in a repeatable bin system often lowers long-run costs too, because you avoid constantly buying mismatched baskets or single-use totes that don’t fit shelves.

Consider a shelf that is deep but not tall. Loose items sprawl and topple; stacked bins lock in the footprint and add layers without chaos. In a garage, this avoids the domino effect of leaning boxes. In a pantry, consistent bins protect delicate packages while preventing the avalanche of snack bags. For renters, the beauty is reversibility: you gain “built-in” structure without drilling or permanent fixtures, and you can carry the system to your next home with minimal fuss. For small businesses, stacks feed inventory discipline; when each product category has a labeled bin and a fixed slot in a rack, counts and reorders are simpler and errors drop.

There is also a sustainability angle. Durable, nestable or stackable bins reduce reliance on disposable packaging and single-use storage. When you rotate seasonal contents or reassign a bin from closet to office, the same container keeps working. A few practical advantages often clinch the case:

– Vertical space becomes usable, not ornamental.

– Contents stay protected from dust and moisture when lids are used.

– Repeated sizes simplify labeling, counting, and restocking.

– Movement is safer and quicker because stacks don’t deform under moderate loads.

Types, Materials, and Design Features

Not all stackable bins are built for the same job. The core variables are material, shape, lid style, and stack mechanism, and each combination suits different conditions. Rigid plastics are the common utility player: polypropylene and polyethylene are widely used for general storage, pantry goods, crafts, and light tools. Clear variants help with visibility; opaque versions block light for photosensitive items or provide visual calm in living areas. Heavy-duty plastics with reinforced corners suit garages and workshops, while open-front “shelf bins” shine where quick reach is essential. Collapsible bins fold flat between uses, saving space in seasonal setups or shared apartments.

Wire or metal baskets bring airflow and strength, useful for laundry rooms, produce, or items that benefit from ventilation. Powder-coated finishes resist corrosion, and the grid lets you clip tags or slide in label cards. Fabric bins—often felt, canvas, or nonwoven—provide a softer look for living rooms and closets. They typically include stiffeners so they hold their shape in a stack, and many come with pull handles to make removal easy from cubbies. For specialty needs, look for containers marked as food-safe for pantry storage, antistatic options for sensitive electronics, and temperature-tolerant bins for garages that swing from hot summers to cold winters. When in doubt, confirm that the material’s operating range and load rating match your intended use.

Design features influence both safety and convenience. Interlocking lids and bases reduce lateral slip across a stack, especially in tall columns. Some lids are flat for stable stacking; others are hinged for quick access without unstacking. Open-front bins trade dust protection for speed; they excel on fixed shelves where you pull parts constantly. Ergonomic cutouts or handholds matter more than people realize: a comfortable grip reduces the temptation to hoist a loaded bin from awkward angles. Label windows, color accents, and clip-on tags turn the stack into a readable map of your stuff.

Choosing among types is easier if you map features to context:

– Kitchen and pantry: clear, food-safe plastic; smooth interiors for easy cleaning; lids to keep dry goods tidy.

– Closet and living areas: fabric or opaque plastic for a calm look; easy-pull handles; consistent sizes for cubbies.

– Garage and workshop: reinforced plastic or metal; open-front for fast access to hardware; lids for dust-prone tasks.

– Office and studio: modular bins that fit standard paper sizes; transparent fronts; dividers for small components.

Planning the Perfect Fit: Sizing, Capacity, and Safety

Great results start with a tape measure. First, measure the width, depth, and height of the space, then subtract a little clearance for fingers and movement. If the bin sits on a shelf, leave room above the top bin to lift the lid or slide the container out. If the stack sits on the floor, check ceiling height, door swing, and how the column might interact with nearby furniture. Standard household shelving often favors medium bins that maximize depth without overhanging, while deep garage shelves can accommodate larger footprints safely. Avoid the temptation to “size up” just because space allows; a fully loaded oversized bin may be cumbersome even for an able adult.

Capacity planning is as much about weight as volume. Assign heavier items to lower bins and keep the total stack within comfortable reach zones—roughly between knee and chest height for frequent use. A simple rule of thumb helps: if you must tip a bin to see inside or feel strain while lifting, the container is either too large, too heavy, or placed too high. Lids and interlocking bases stabilize columns, but they are not substitutes for sensible loading. If the floor is slick, add a non-slip mat under the bottom bin; if the area is earthquake-prone or vibration-heavy, consider low-profile stacks or shelf-based bins that do not rely on height.

Plan your internal organization as well. Group items by task or frequency, not just category. For example, a “Morning kit” bin in a closet could hold gym bands, socks, and a small towel—everything you grab while half-awake. In a pantry, use dividers inside a bin to separate snacks from baking supplies, rather than creating two half-empty containers. Label placement should be consistent across the face that you see first; adopt a simple format like noun + size or noun + date. Add secondary labels for rotation-sensitive items (e.g., “Open first”).

Safety deserves a checklist:

– Heaviest bins at the bottom; reduce load as you go higher.

– Keep the top of the stack below eye level if you access it daily.

– Ensure lids fully seat before adding another bin.

– Avoid overhang beyond shelves; maintain even weight distribution.

– Leave pathways clear; a stable stack still needs safe approach angles.

For shared spaces, post a quick guide near the stack: who maintains labels, when to purge or reorder, and what belongs where. Clear norms preserve order long after the initial setup glow fades.

Real-World Setups: Home, Garage, Office, and Small Business

Pantry and kitchen: use clear, food-safe bins for snacks, pasta, and baking goods, and choose shallow sizes for top shelves so nothing hides behind something else. Lidded stacks keep flour, sugar, and bulk ingredients shielded from humidity, while open-front shelf bins hold spice packets or tea. Try grouping by meal type: “Breakfast,” “Quick dinners,” and “Baking basics.” This approach reduces scatter and supports a simple restock routine. Rotate items forward when you add new groceries and place soon-to-expire goods in the uppermost or frontmost spot so they’re grabbed first.

Closet and bedroom: soft-sided or opaque plastic bins calm visual noise and make seasonal swaps painless. Dedicate one stack to off-season wear, another to accessories, and a small one to repair supplies like sewing kits and spare buttons. Label by category and season to avoid rummaging. In kids’ rooms, color-coding can be more effective than text labels; children learn quickly that green bins hold building blocks and blue bins hold art supplies. Make daily-use bins easy to reach and keep “display” shelves clutter-free by funneling extras into clearly marked containers.

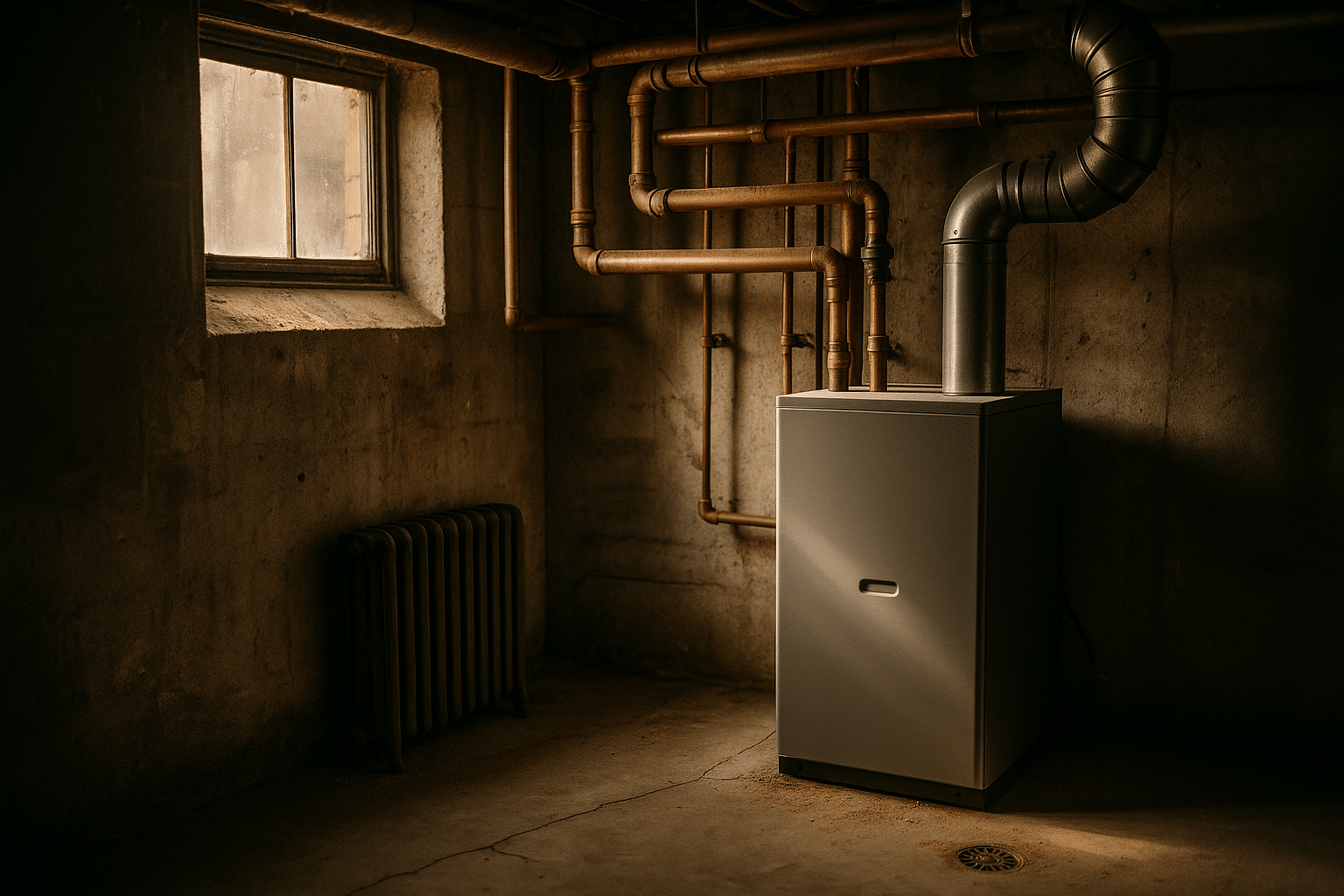

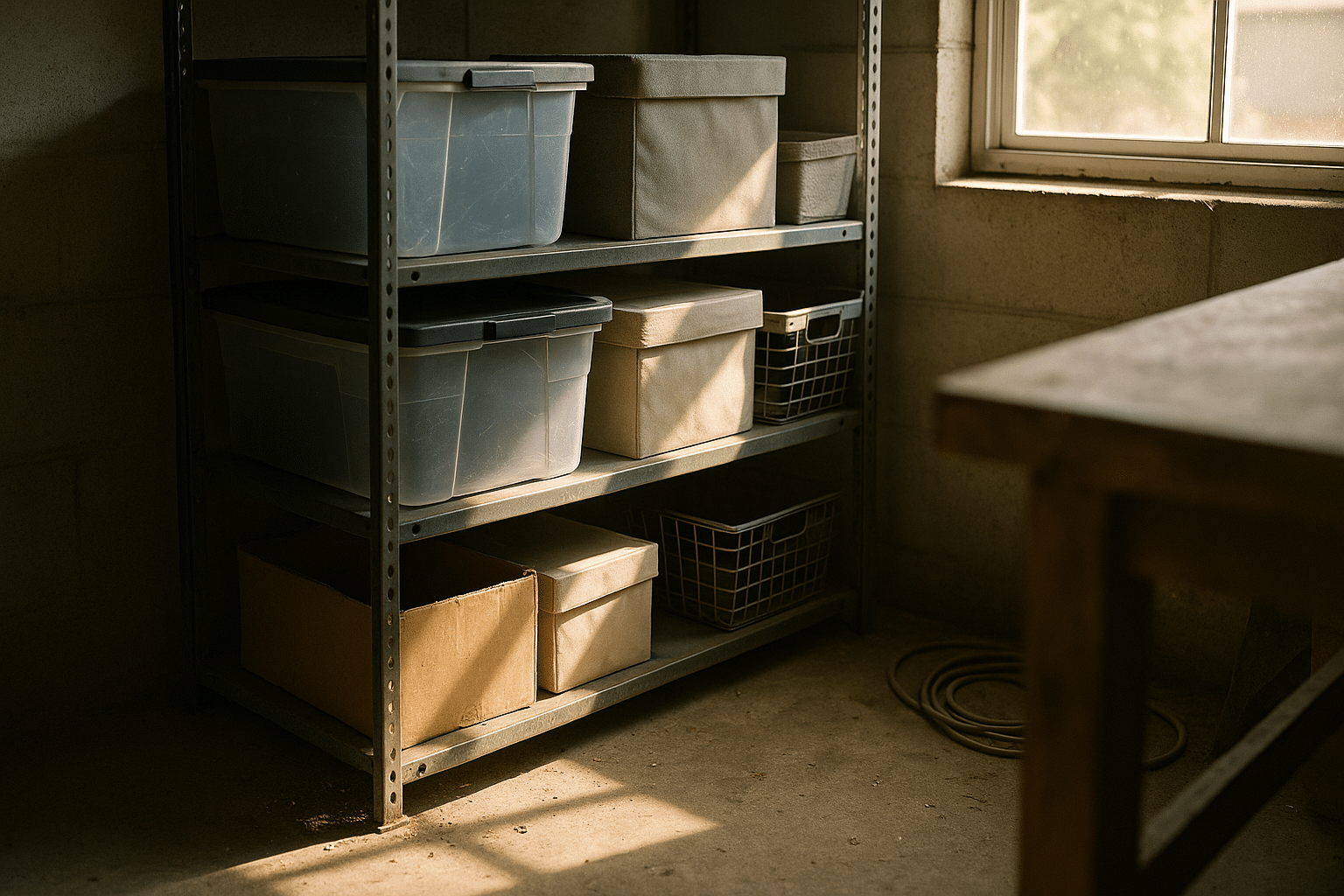

Garage and workshop: dust and grit argue for lids, and weight argues for reinforced plastics or metal. Open-front bins are helpful for screws, nails, and small parts you reach for constantly, while lidded totes tackle seasonal gear or paint supplies. If you maintain equipment, dedicate a vertical column per machine—mower, trimmer, bicycle tools—so each project has a self-contained kit. For safety, keep chemicals in a single, labeled stack away from heat sources and out of reach of children and pets. If the floor gets damp, lift stacks onto a low shelf or a dolly to protect the bottom bin.

Office, studio, and classroom: document-sized bins prevent bent corners on paper and store stationery, cables, and peripherals by function. Transparent fronts help you spot printer paper or watercolor pads at a glance. Creators benefit from dividing a single stack by project with labeled bins: “Draft,” “In progress,” and “Archive.” This keeps momentum visible without spreading materials across every flat surface. Portable half-height bins are handy for meeting kits or workshops; they slide into a larger stack when the event ends.

Small business and stockroom: repeatability pays off here. Choose one or two bin sizes that fit your shelving pattern and commit to them. Assign every SKU to a labeled bin and reserve buffer space for incoming stock. Open-front bins speed picking; lidded bins protect returns or fragile items. A weekly bin audit—five minutes per aisle—catches misplacements before they ripple into shipping errors. For quick wins, add simple signposts:

– Aisle letters on shelf ends; bin labels with big, high-contrast text.

– Color bands to signal product families.

– A “quarantine” stack for damaged or to-be-checked items.

Conclusion and Long-Term Organizing Playbook

Stackable bins earn their keep when they support habits, not just storage. For homeowners and renters, that means choosing a few compatible sizes, labeling them plainly, and putting them in the path of daily routines. For makers and small retailers, it means standardizing bins across the workspace so inventory, tools, and paperwork live in known homes. The payoff is less hunting, faster resets, and a system that flexes as seasons and projects change. Think of stacks as a modular language: once you learn a few “words” (size, label, location), you can express any setup without rebuilding from scratch.

Adopt a simple cadence that keeps the system fresh:

– Monthly: five-minute tidy of each stack; return strays and refresh labels.

– Quarterly: purge duplicates, donate unused items, and reassign bins to match current projects.

– Seasonally: rotate clothes, sports gear, or holiday decor; inspect lids, corners, and grips for wear.

– Annually: wash or wipe bins, check for cracked edges, and reevaluate sizes against changing needs.

Care extends bin life and keeps contents safe. Smooth plastics wipe clean with mild soap; avoid abrasive pads that cloud transparent walls. Fabric bins benefit from a vacuum pass to remove dust; spot clean and let them dry fully before restacking. Metal baskets appreciate a quick check for rust in damp climates; a light protective coat can help in garages. Keep stacks away from heaters, direct sun, and persistent moisture; even sturdy materials last longer when conditions are gentle. If a bin shows stress marks or a loosened handle, demote it to lighter duty rather than force a failure.

When you expand your system, resist mixing too many odd sizes that break alignment. Add a matching column or swap a stack’s role instead. If space changes—new shelf, new room, new team—your bins move with you and reassemble into a familiar pattern. That portability is the quiet advantage of stackable storage: structure you can carry. In short, pick a coherent set, load by frequency and weight, label consistently, and review on a schedule. Do that, and your bins will feel less like boxes and more like teammates that keep life and work moving smoothly.